Abb

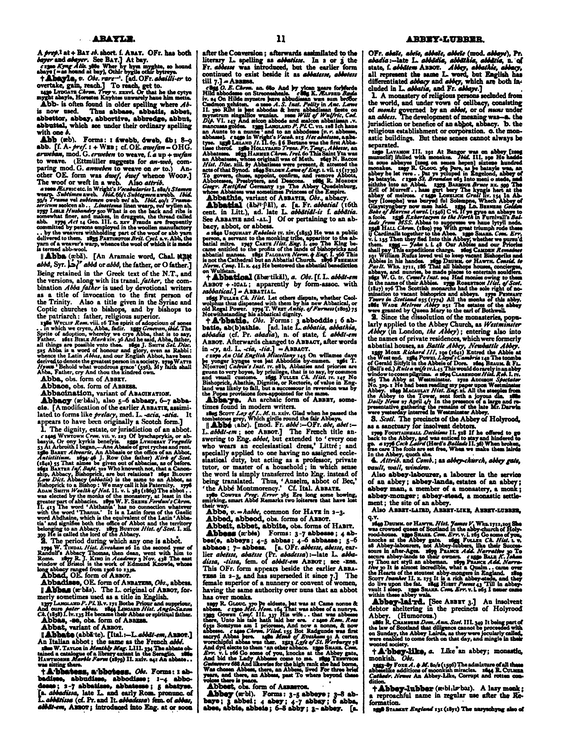

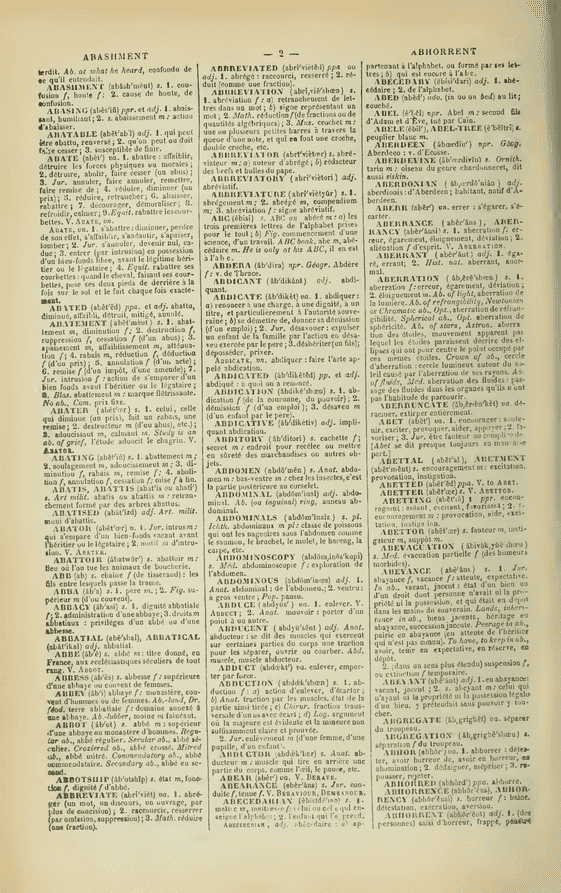

Source : Oxford Dictionary

The woof or weft in a web The waft of a weaver's warp

The warp threads are arranged vertically, from bottom to top, on the loom. The weft, on the other hand, is woven through the warp from left to right (or vice versa, depending on the weaving method).

Le fil de trame dans une toile Le passage du fil dans la chaîne du tisserand

La chaîne désigne les fils de la toile qui sont disposés de manière verticale, tandis que la trame ou le fil de trame traverse la chaîne de manière horizontale pour former le tissu.

Source : Century Dictionary web : http://triggs.djvu.org/century-dictionary.com/splash3.html

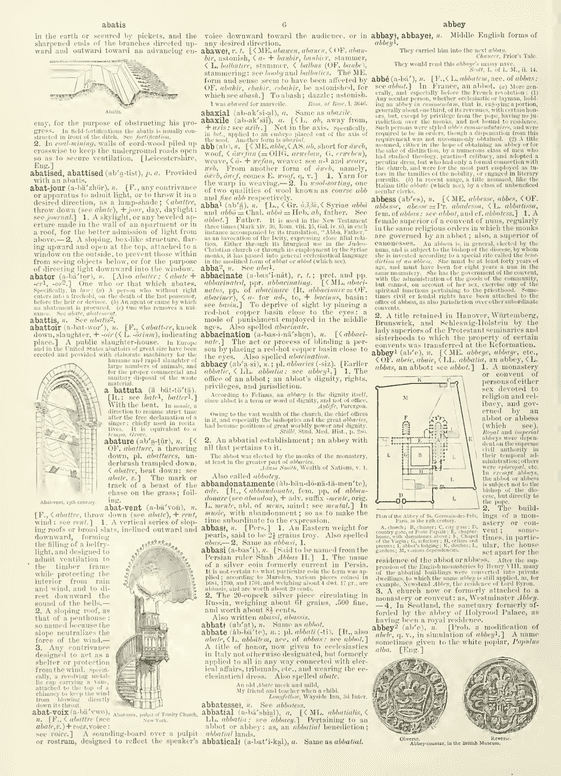

Source : Percy Sadler

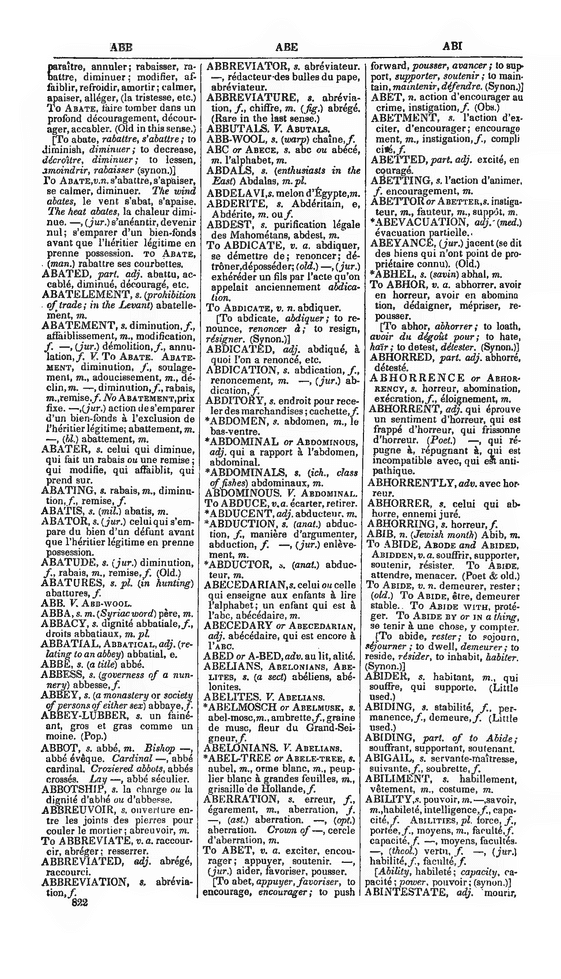

Source : A NEW AND COMPLETE FRENCH AND ENGLISH AND ENGLISH AND FRENCH DICTIONARY, ON THE BASIS OF THE EOYAL DICTIONARY ENGLISH AND FRENCH AND FRENCH AND ENGLISH

Source : Nouveau Dictionaire Anglais Français par E.C. Clifton et A. Grimaux

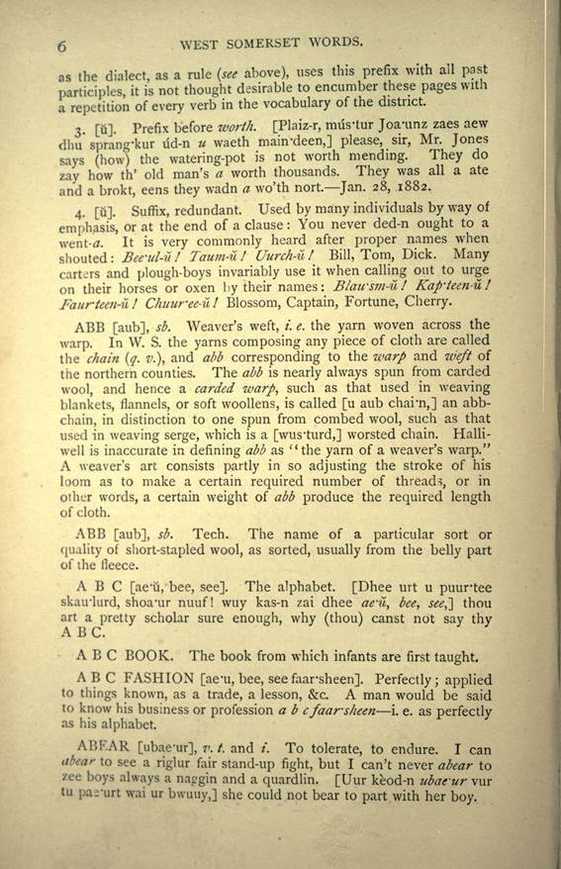

Source : THE WEST SOMERSET WORD-BOOK. OF DIALECTAL AND ARCHAIC WORDS AND PHRASES USED IN THE WEST OF SOMERSET AND EAST DEVON. BY FREDERICK THOMAS ELWORTHY, MEMBER OF COUNCIL OF THE PHILOLOGICAL SOCIETY.

ABB , sb. Weaver's weft, /. e. the yarn wovenacross the warp. In W. S. the yarns composing anypiece of cloth are called the chain (q. v.\ andabb corresponding to the warp and weft of the northerncounties. The abb is nearly always spun from carded wool,and hence a carded warp, such as that used in weavingblankets, flannels, or soft woollens, is called an abb-chain,in distinction to one spun from combed wool, such as thatused in weaving serge, which is a worsted chain.Halliwell is inaccurate in defining abb as "the yarn of aweaver's warp." A weaver's art consists partly in soadjusting the stroke of his loom as to make a certainrequired number of threads, or in other words, acertain weight of abb produce the required length of cloth.

ABB , sb. Tech. The name of a particular sort orquality of short-stapled wool, as sorted, usually fromthe belly part of the fleece.

The next process was weaving. Weavers had to collect their yarn from the clothier’s mill, usually on a particular day of the week, ‘bearing home day’, when finished cloth was returned and new work given out. Warp yarn was measured out by winding it around two pegs set in a wall and then handed over to the weavers together with skeins of weft yarn, referred to in the West as ‘abb’, to be carried back to the weaver’s cottage to be woven into cloth. Weavers often referred to this as collecting a new ‘chain’ but technically chain was the name given to warp yarn. The principal production of the West of England throughout the period under review was broadcloth which was woven in the double loom and needed two weavers to throw the shuttle from side to side until the flying shuttle loom made one redundant. A child was also needed to quill, that is, to wind the weft onto the bobbin of the shuttle. Narrow cloth, of growing importance from 1766, was woven by a single weaver in a narrow loom. There were two sorts of weaver in the West of England, those who owned their own loom and those journeymen who worked a loom for a master weaver. It was very rare, and very much resented, for a clothier to own looms and rent them to weavers. There is little evidence of the number of master weavers. The term was often used indiscriminately to describe not only employers of journeymen but also men who owned their own loom and employed merely their wives and children to help them. Indeed, this latter was the characteristic unit of production in the West of England and the family economy was much prized by the weavers.